Home / All / Tape Wrapping Machine /

TR-SC26 Semi-auto Rechargeable Lithium Battery Electric Handheld Tape Wrapping Machine with Fixed Base for Wire Harness

TR-SC26 Semi-auto Rechargeable Lithium Battery Electric Handheld Tape Wrapping Machine with Fixed Base for Wire Harness

Detail Information

TR-SC26 Semi-auto Rechargeable Lithium Battery Electric Handheld Tape Wrapping Machine with Fixed Base for Wire Harness

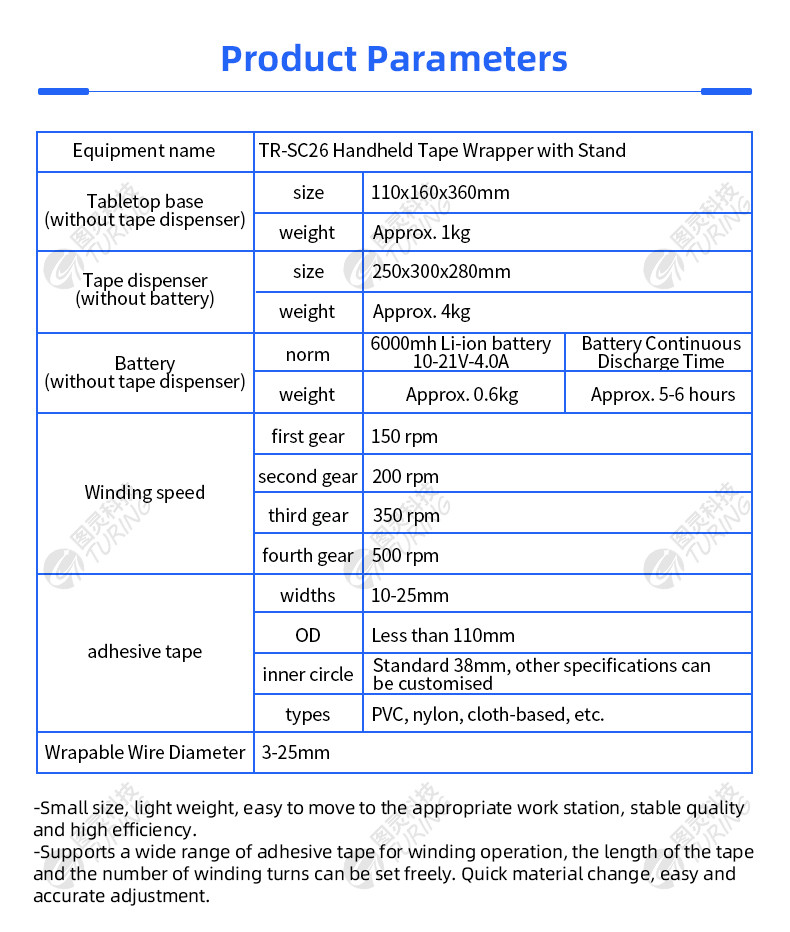

Tabletop base (without tape dispenser) size&weight:110x160x360mm,approx. 1kg

Tape dispenser (without battery) size&weight:250x300x280mm,approx. 4kg

Battery

(without tape dispenser) norm:6000mh Li-ion battery

10-21V-4.0A;weight:Approx. 0.6kg;Battery Continuous Discharge Time:Approx. 5-6 hours

Winding speed

first gear:150 rpm;second gear:200 rpm;

third gear:350 rpm;fourth gear:500 rpm

Adhesive tape

widths:10-25mm;

OD:Less than 110mm;

inner circle:Standard 38mm, other specifications can

be customised;

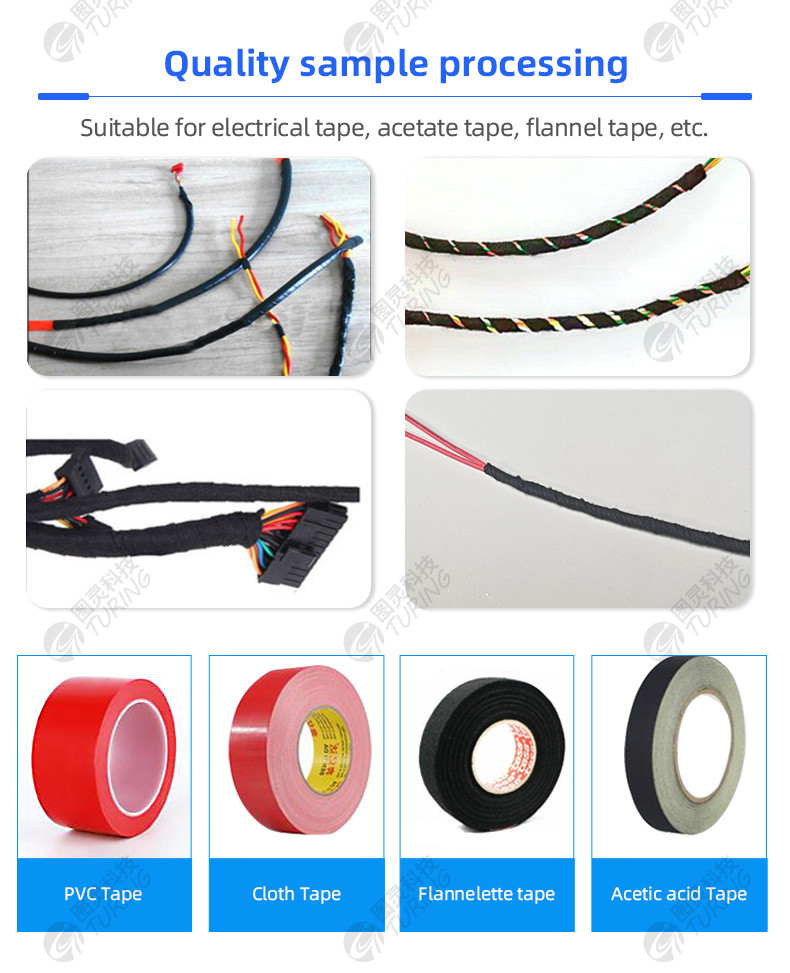

types:PVC, nylon, cloth-based, etc.

Wrapable Wire Diameter:3-25mm

-Small size, light weight, easy to move to the appropriate work station, stable quality and high efficiency.

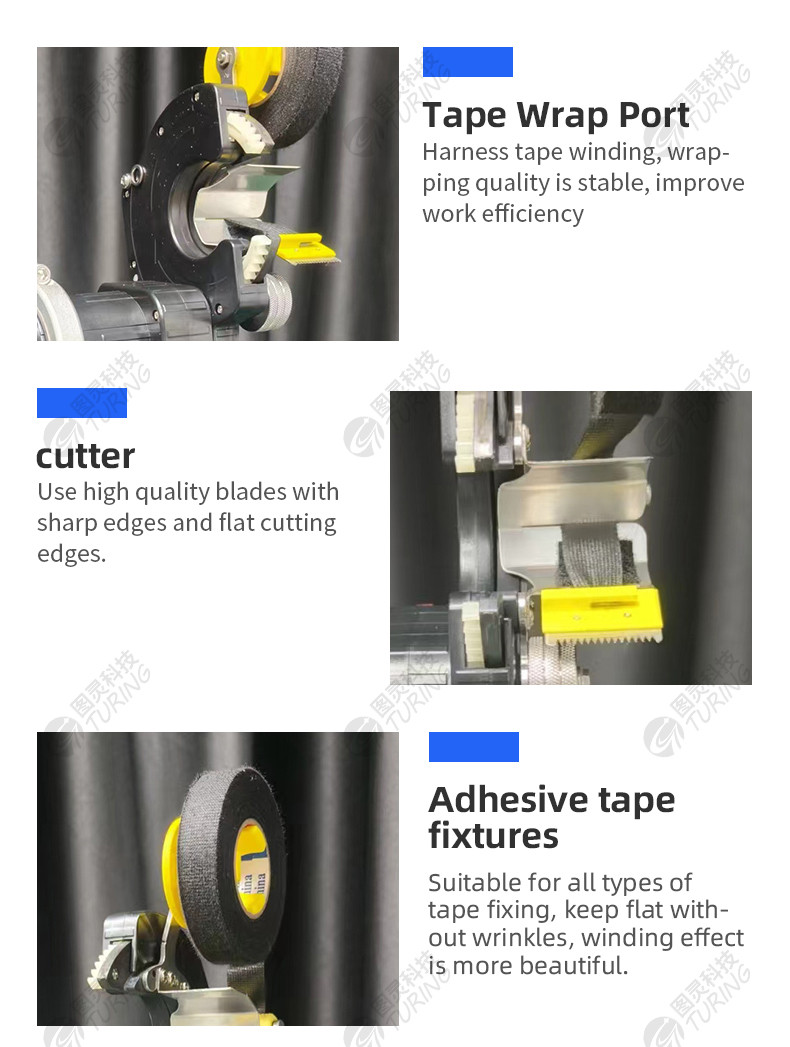

-Supports a wide range of adhesive tape for winding operation, the length of the tape and the number of winding turns can be set freely. Quick material change, easy and accurate adjustment.

This machine is small and flexible. The weight of the machine is only 1.65kg, and the machine has a hooked rope, which can be hung in the air to share and bear part of the weight, and the open design can start wrapping from any position of the wire harness, and it's easy to skip the branches, it is suitable for tape wrapping of wire harnesses with branches, Of ten used for wire harness assembly board to assemble wire harness.

Advantage

1. Can work with many kinds of material tapes

2. Lightweight, easy to move and not easy to feel tired, high efficiency

3. Simple operation, operators only need simple exercises

4. Easily adjust the distance of the tape and overlap, reducing the waste of tape

5. After cutting the tape, the tool automatically jumps to the next position for the next preparation, no additional process

6. The finished products have appropriate tension and no wrinkle

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat shrink tube baking machine

- Pay-off rack

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content