TR-JL05 Single Rivet Caster Brake Assembly Machine

Detail Information

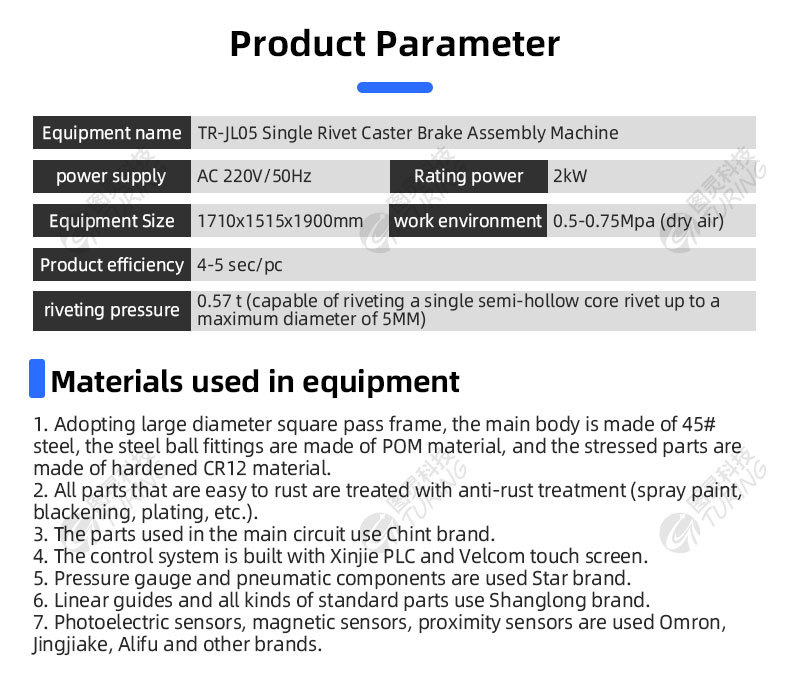

TR-JL05 Single Rivet Caster Brake Assembly Machine

Power supply : AC 220V/50Hz,2kW

Equipment Size : 1710x1515x1900mm

Work environment : 0.5-0.75Mpa (dry air)

Product efficiency : 4-5 sec/pc

Riveting pressure : 0.57 t (capable of riveting a single semi-hollow core rivet up to a

maximum diameter of 5mm)

Equipment features

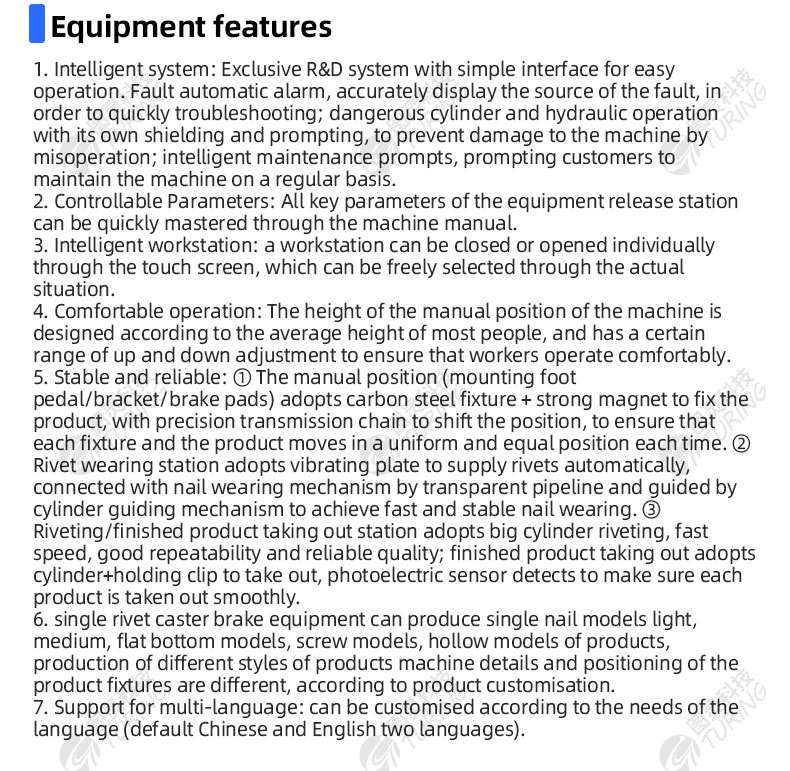

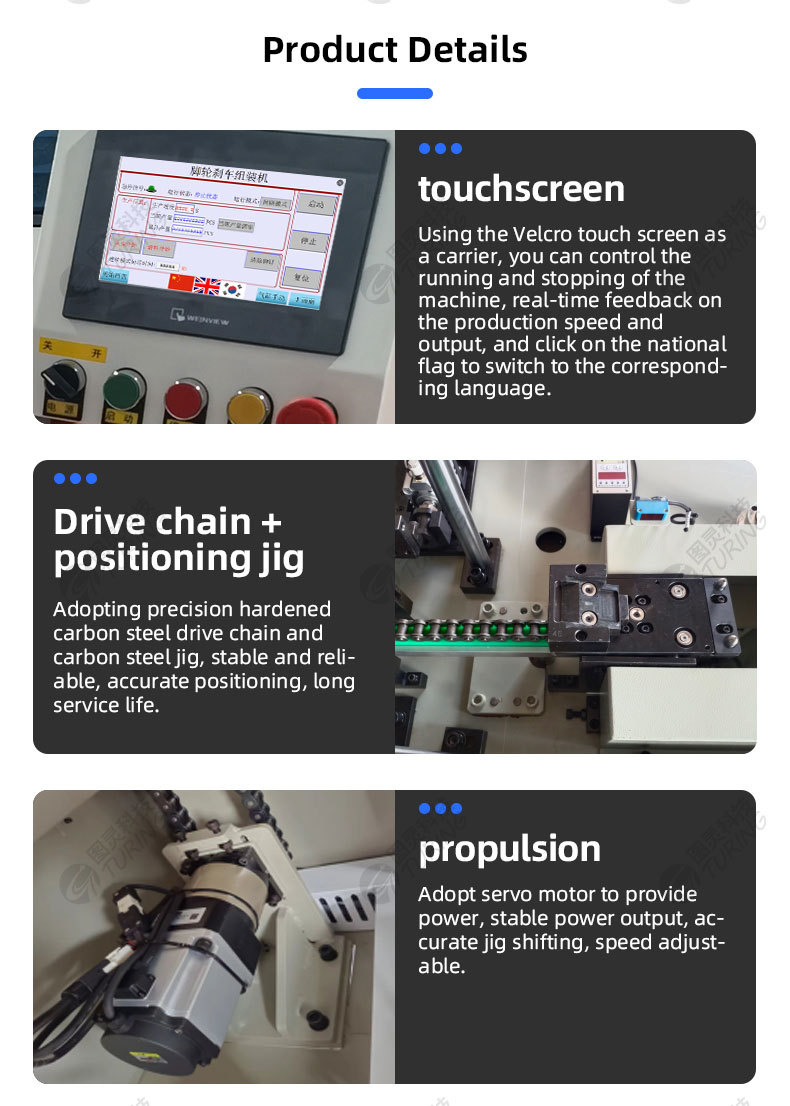

1. Intelligent system: Exclusive R&D system with simple interface for easy operation. Fault automatic alarm, accurately display the source of the fault, in order to quickly troubleshooting; dangerous cylinder and hydraulic operation with its own shielding and prompting, to prevent damage to the machine by misoperation; intelligent maintenance prompts, prompting customers to maintain the machine on a regular basis.

2. Controllable Parameters: All key parameters of the equipment release station can be quickly mastered through the machine manual.

3. Intelligent workstation: a workstation can be closed or opened individually through the touch screen, which can be freely selected through the actual situation.

4. Comfortable operation: The height of the manual position of the machine is designed according to the average height of most people, and has a certain range of up and down adjustment to ensure that workers operate comfortably.

5. Stable and reliable:

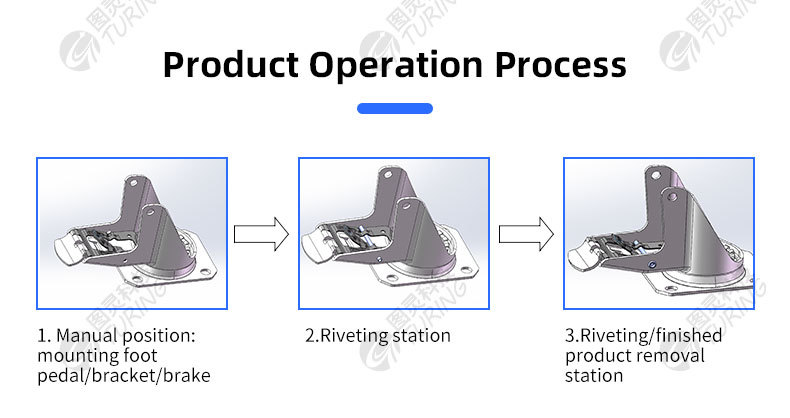

① The manual position (mounting foot pedal/bracket/brake pads) adopts carbon steel fixture + strong magnet to fix the product, with precision transmission chain to shift the position, to ensure that each fixture and the product moves in a uniform and equal position each time.

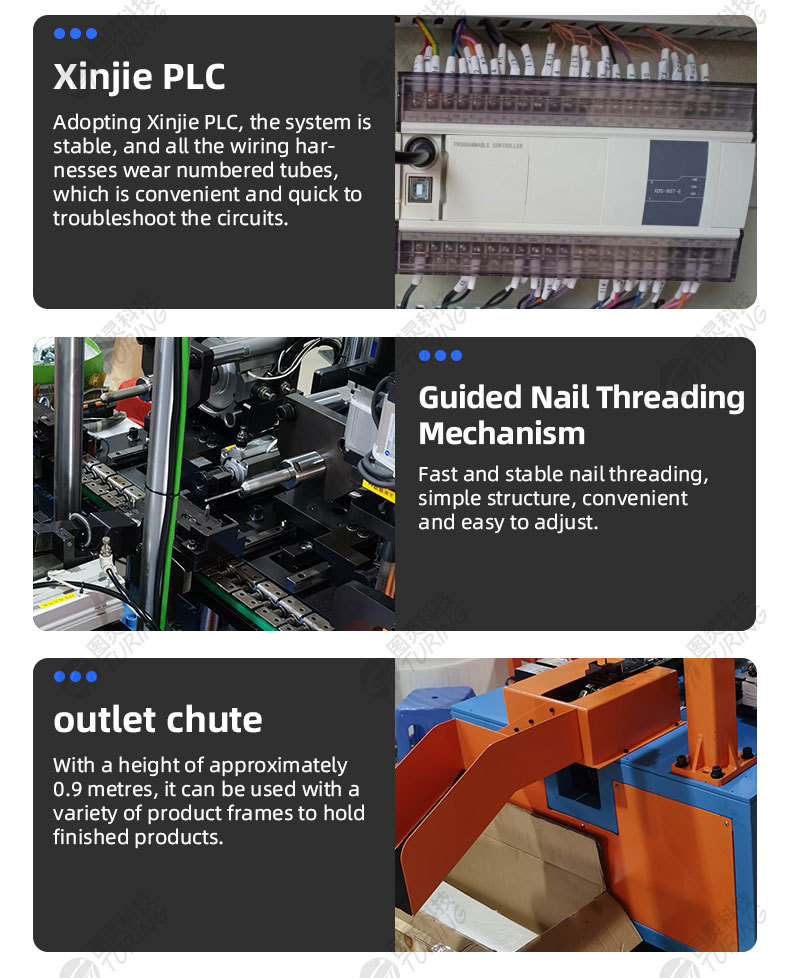

② Rivet wearing station adopts vibrating plate to supply rivets automatically, connected with nail wearing mechanism by transparent pipeline and guided by cylinder guiding mechanism to achieve fast and stable nail wearing.

③ Riveting/finished product taking out station adopts big cylinder riveting, fast speed, good repeatability and reliable quality; finished product taking out adopts cylinder+holding clip to take out, photoelectric sensor detects to make sure each product is taken out smoothly.

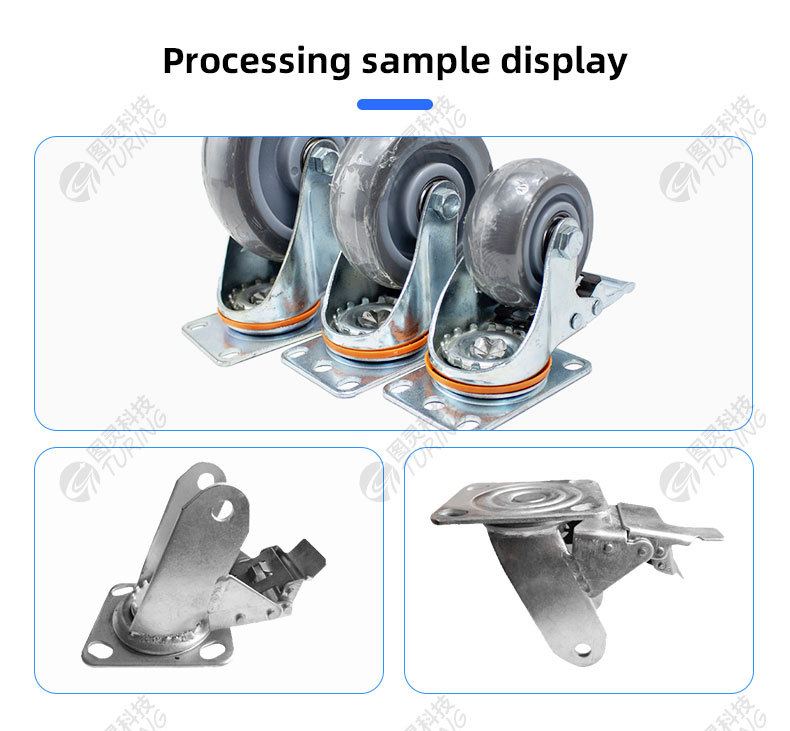

6. single rivet caster brake equipment can produce single nail models light, medium, flat bottom models, screw models, hollow models of products, production of different styles of products machine details and positioning of the product fixtures are different, according to product customisation.

7. Support for multi-language: can be customised according to the needs of the language (default Chinese and English two languages).

Materials used in equipment

1. Adopting large diameter square pass frame, the main body is made of 45# steel, thesteel ball fittings are made of POM material, and the stressed parts are made of hardened

CR12 material.

2. All parts that are easy to rust are treated with anti-rust treatment (spray paintblackening, plating, etc.).

3. The parts used in the main circuit use Chint brand.

4. The control system is built with Xinjie PLc and Velcom touch screen.

5. Pressure gauge and pneumatic components are used Star brand.

6. Linear quides and all kinds of standard parts use Shanglong brand.

7. Photoelectric sensors, magnetic sensors, proximity sensors are used Omron, jingjiakeAlifu and other brands.

Equipment Description

1. Intelligent system: Exclusive R&D system with simple interface for easyoperation. Fault automatic alarm, accurately display the source of the fault, inorder to quickly troubleshooting; dangerous cylinder and hydraulic operationwith its own shielding and prompts to prevent damage to the machine by misuse;intelligent maintenance prompts, prompting customers to maintain the machineon a regular basis.

2. Controllable Parameters: All key parameters of the equipment release stationcan be quickly mastered through the machine manual.

3. Intelligent workstation: a workstation can be individually closed or openedthrough the touch screen, which can be freely selected through the actualsituation.

4. Comfortable operation: The height of the manual position of the machine isdesigned according to the average height of most people, and has a certainrange of up and down adjustment to ensure that workers operate comfortably.Stable and reliable:

①Manual position (put the bracket to the turntable jig; transfer the bracket withthe steel ball to the big bobbin plate; put on the small plucking plate).

②) Load mandrel/bottom plate, manually stack the bottom plate into the materialchute, the cylinder mechanism automatically discharges the material to theconveyor line, the mandrel is automatically threaded and then clamped by thecylinder guide mechanism and put into the turntable fixture, the mandrel isautomatically loaded by the vibrating disc. The mandrel threading mechanismwith guiding function ensures the fast and stable threading of nails every time.

③Install the big pulling disc, the big pulling disc is automatically loaded by thevibrating disc, and put into the turntable fixture by the cylinder guide mechanism+strong magnet suction method.

③The oiling station uses the oil cylinder transfer station and quantitative valve todispense oil, which is accurately controlled by stepping motor to ensure the oilquantity of each product is uniform and even.

⑤ Big pulling plate/stands loading steel ball, loading steel ball station usingcustom mould vacuum suction, with negative pressure gauge detection, toensure that the number of steel balls of each product.

(6) Riveting, the riveting station adopts the hydraulic station of vane pump withoil cylinder to achieve riveting, with good repeatability, reliable quality and fastspeed.

(7)Finished products take out, using multi-stage cylinder + strong magnetic ringto ensure that each product can be taken out smoothly.

(8) bottom plate rotation detection (Note: this station is non-standard optionalstation), the use of servo motors + pneumatic clamp mode, can detect the bottomplate and bracket riveting whether the flexible rotation, OK products and NGproducts can be automatically differentiated into separate open material frame.5. Support multi-language: customised language according to demand (defaultChinese and English two languages),

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat shrink tube baking machine

- Pay-off rack

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content