Home / All / Others / Caster Assembly Machine /

TR-JL01 fully automatic furniture wheel assembly machine

TR-JL01 fully automatic furniture wheel assembly machine

Detail Information

TR-JL01 fully automatic furniture wheel assembly machine

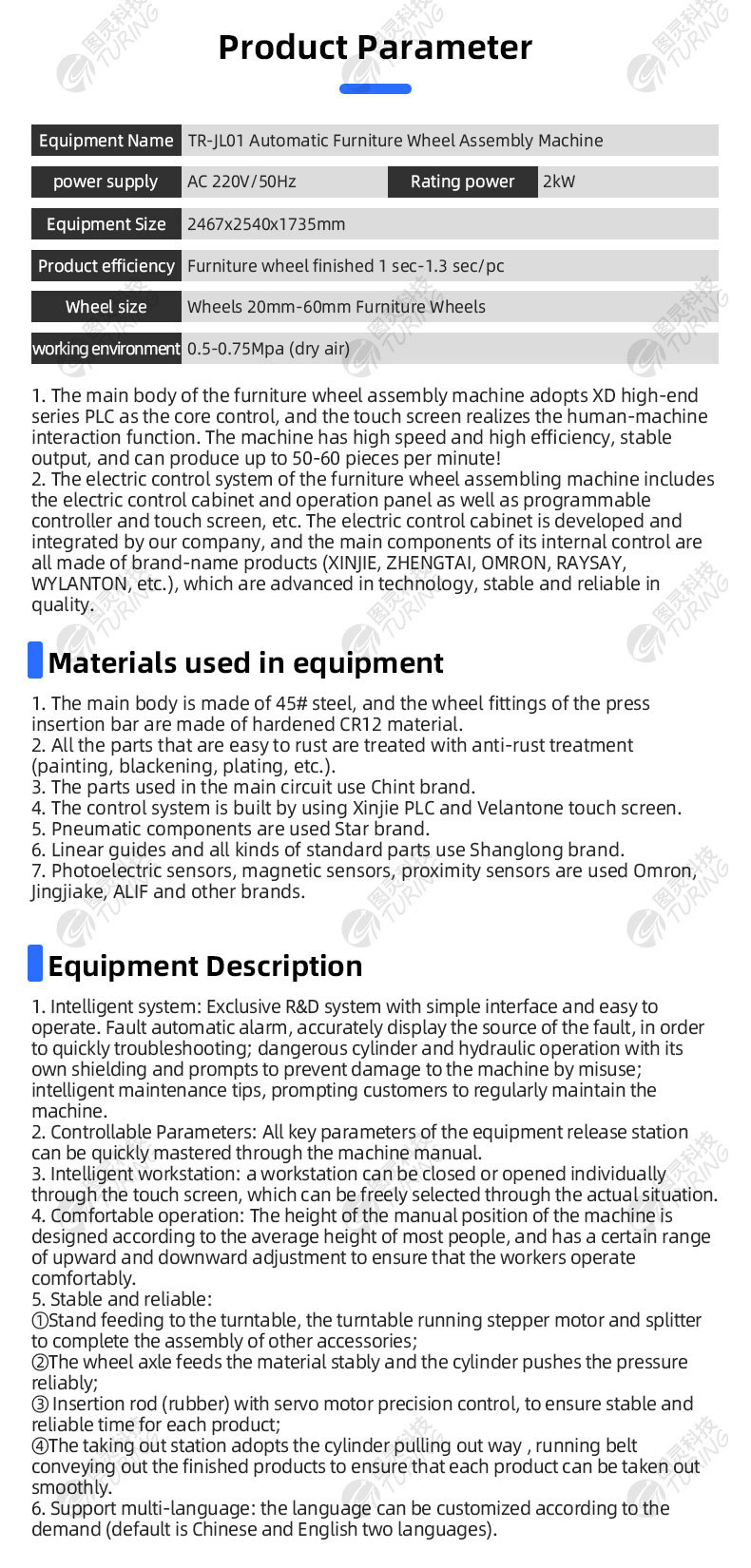

1. The main body of the furniture wheel assembly machine adopts XD high-endseries PLC as the core control, and the touch screen realizes the human-machineinteraction function. The machine has high speed and high efficiency, stableoutput, and can produce up to 50-60 pieces per minute!

2. The electric control system of the furniture wheel assembling machine includesthe electric control cabinet and operation panel as well as programmablecontroller and touch screen, etc. The electric control cabinet is developed andintegrated by our company, and the main components of its internal control areall made of brand-name products (XINJIE, ZHENGTAI, OMRON, RAYSAY,WYLANTON, etc.), which are advanced in technology, stable and reliable inquality.

Equipment Description

1.Intelligent system: Exclusive R&D system with simple interface and easy tooperate. Fault automatic alarm, accurately display the source of the fault, in orderto quickly troubleshooting; dangerous cylinder and hydraulic operation with itsown shielding and prompts to prevent damage to the machine by misuse;intelligent maintenance tips, prompting customers to regularly maintain themachine.

2. Controllable Parameters: All key parameters of the equipment release stationcan be quickly mastered through the machine manual.

3. Intelligent workstation: a workstation can be closed or opened individuallythrough the touch screen, which can be freely selected through the actual situation.

4. Comfortable operation: The height of the manual position of the machine isdesigned according to the average height of most people, and has a certain rangeof upward and downward adjustment to ensure that the workers operatecomfortably.

5. Stable and reliable:

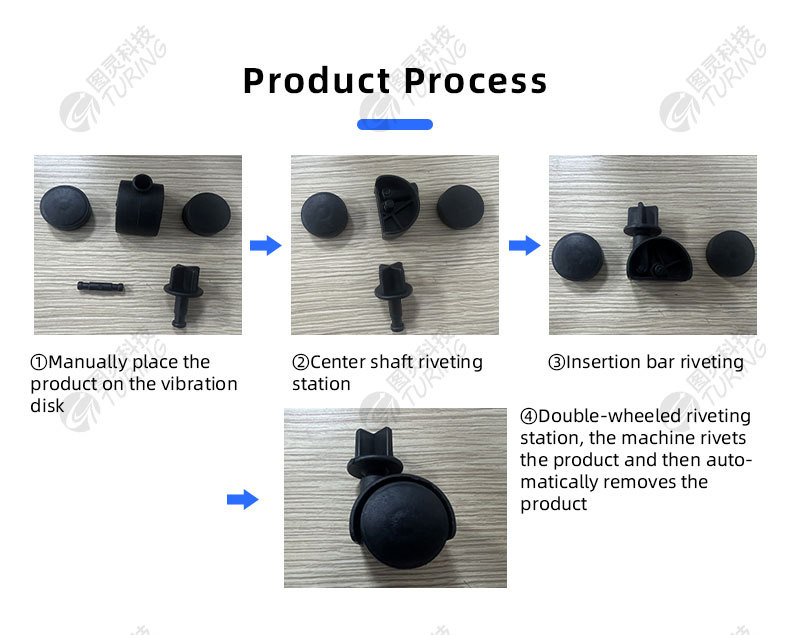

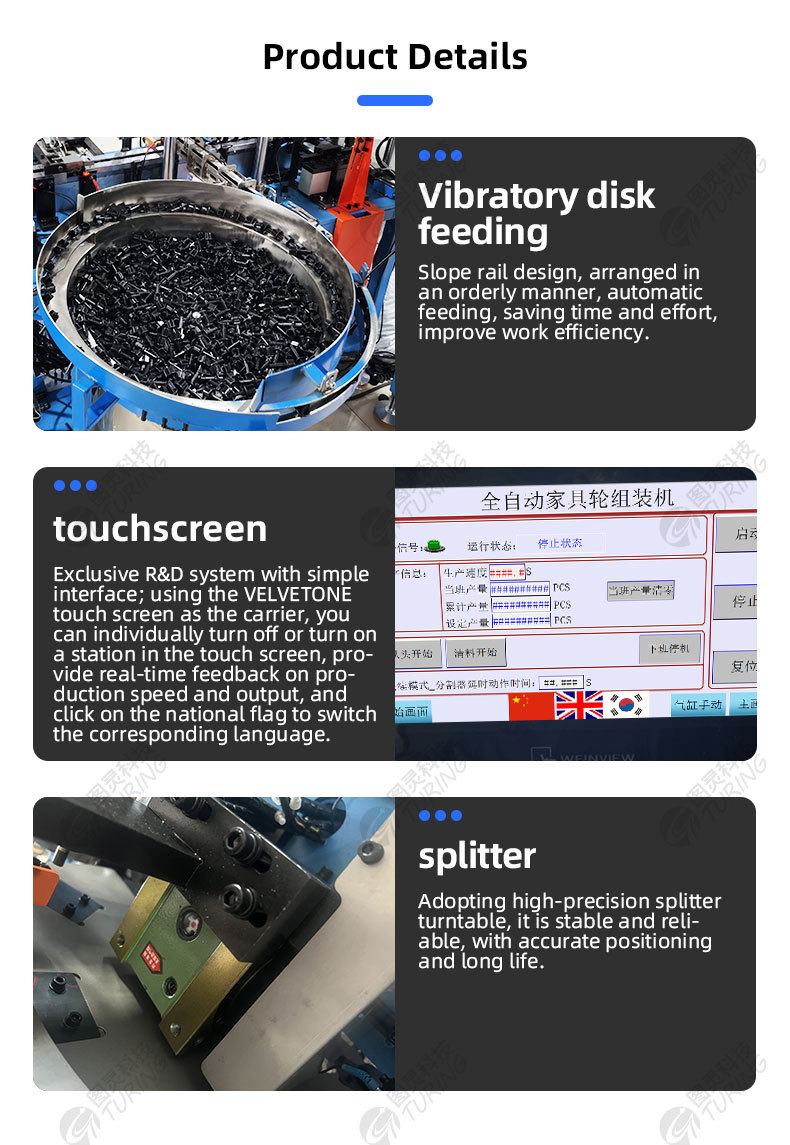

①Stand feeding to the turntable, the tumtable running stepper motor and splitterto complete the assembly of other accessories;

②The wheel axle feeds the material stably and the cylinder pushes the pressurereliably;

③Insertion rod (rubber) with servo motor precision control, to ensure stable andreliable time for each product;

④The taking out station adopts the cylinder pulling out way , running beltconveying out the finished products to ensure that each product can be taken outsmoothly

6. Support multi-language: the language can be customized according to thedemand (default is Chinese and English two languages).

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat shrink tube baking machine

- Pay-off rack

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content