Home / All / Cable/Wire Cutting and Stripping Machine / Computer Wire Stripping Machine /

TR-880L fully automatic sheathed core wire inner and outer sheath stripping machine

TR-880L fully automatic sheathed core wire inner and outer sheath stripping machine

Detail Information

TR-880L fully automatic sheathed core wire inner and outer sheath stripping machine

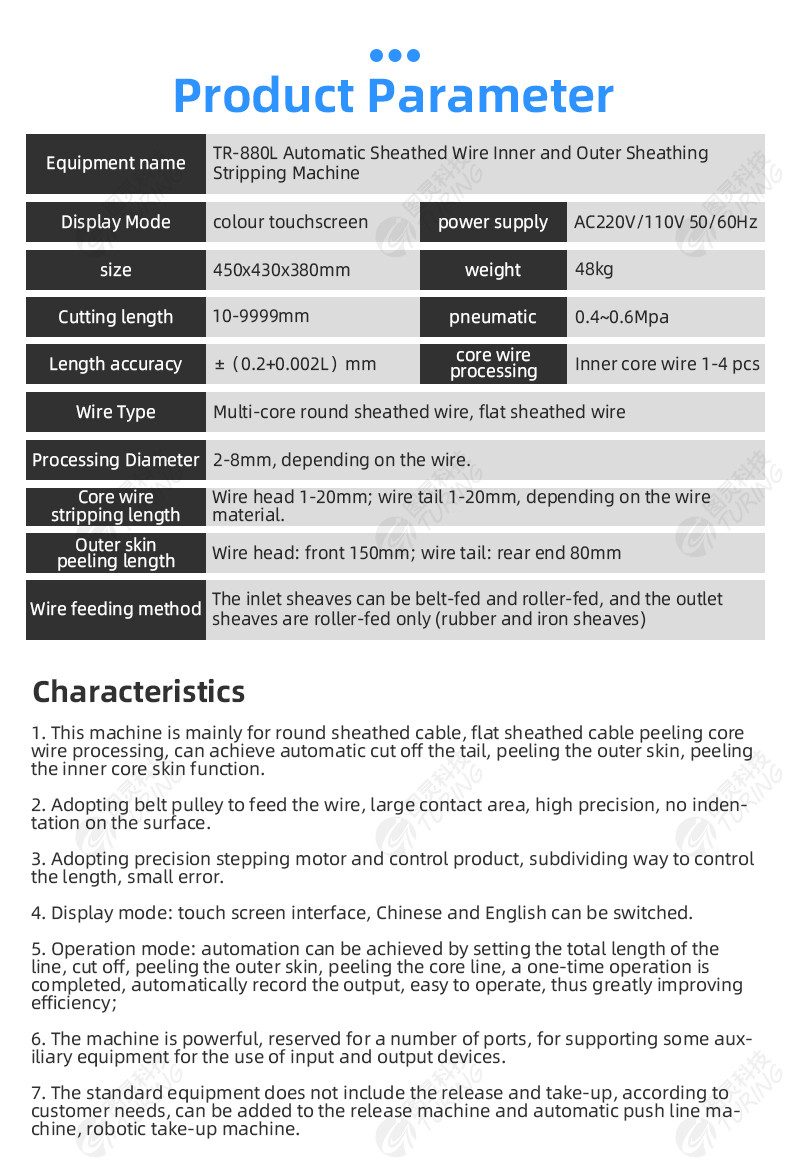

Characteristics

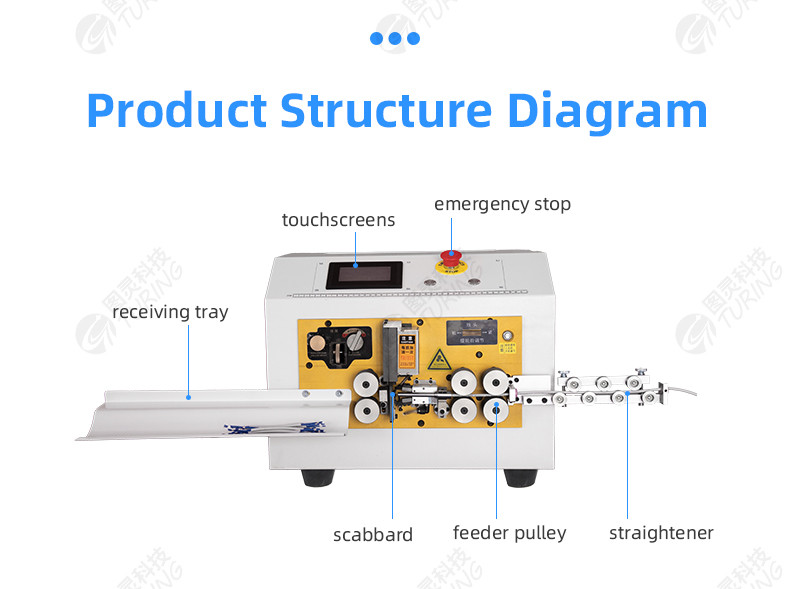

1. This machine is mainly for round sheathed cable, flat sheathed cable peeling coreWire processing, can achieve automatic cut off the tail, peeling the outer skin, peelingthe inner core skin function.

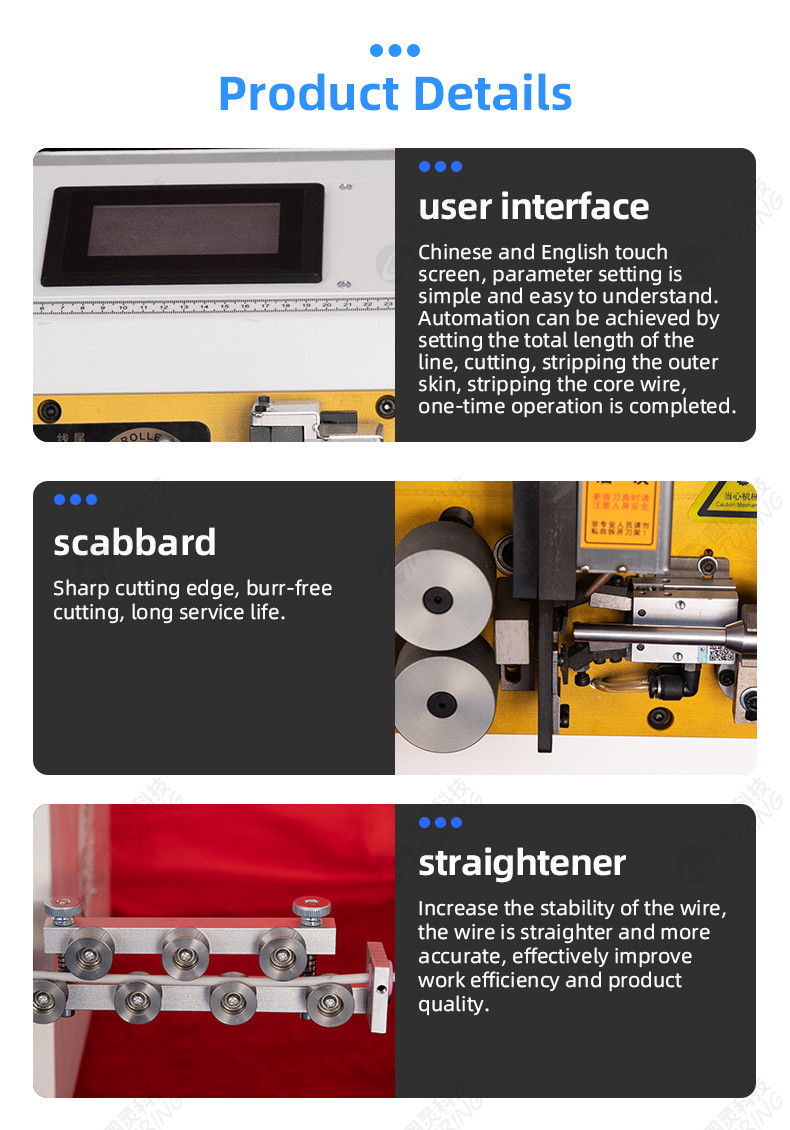

2. Adopting belt pulley to feed the wire, large contact area, high precision, no inden-tation on the surface.

3. Adopting precision stepping motor and control product, subdividing way to controlthe length,small error.

4. Display mode: touch screen interface, Chinese and English can be switched.

5. Operation mode: automation can be achieved by setting the total length of theline, cut off, peeling the outer skin, peeling the core line, a one-time operation iscompleted, automatically record the output, easy to operate, thus greatly improvingefficiency;

6. The machine is powerful, reserved for a number of ports, for supporting some aux-iliary equipment for the use of input and output devices.

7. The standard equipment does not include the release and take-up, according tocustomer needs, can be added to the release machine and automatic push line ma.chine,robotic take-up machine.

Characteristics

1. This machine is mainly for round sheathed cable, flat sheathed cable peeling corewire processing, can achieve automatic cut off the tail, peeling the outer skin, peel-ing the inner core skin function.

2. Adopting belt wheel to feed the wire, large contact area, high precision, no sur-face indentation.

3. Adopt servo drive, subdividing way to control the length, small error.

4. Display mode: touch screen interface, 10-inch touch screen, Chinese and Englishcan be switched.

5.Operation mode: it can realise semi-automatic manual operation of length mea.surement, cutting, multi-layer peeling, middle peeling and automatic note produc-tion, which is easy to operate, thus greatlyimproving the efficiency;

6. The machine is powerful, reserved for a number of ports, for supporting someauxiliary equipment input and output devices.

7. Auxiliary equipment: automatic wire feeder, take-up machine, robot, windingmachine and so on.

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat shrink tube baking machine

- Pay-off rack

- Copper stripping machine

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content