Home / All / Cutting Machine / Tape Cutting Machine /

TR-EVA1 High-speed punching and cutting machine

TR-EVA1 High-speed punching and cutting machine

Detail Information

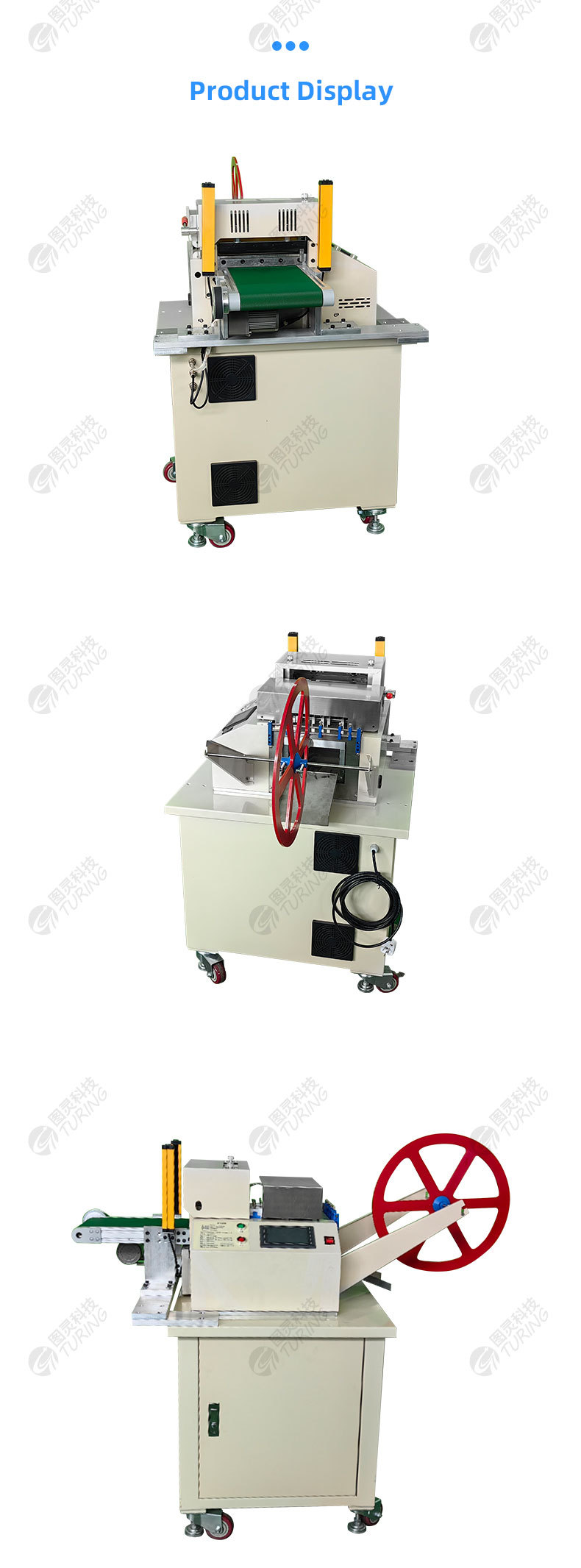

TR-EVA1 High Speed Perforating and Cutting Machine

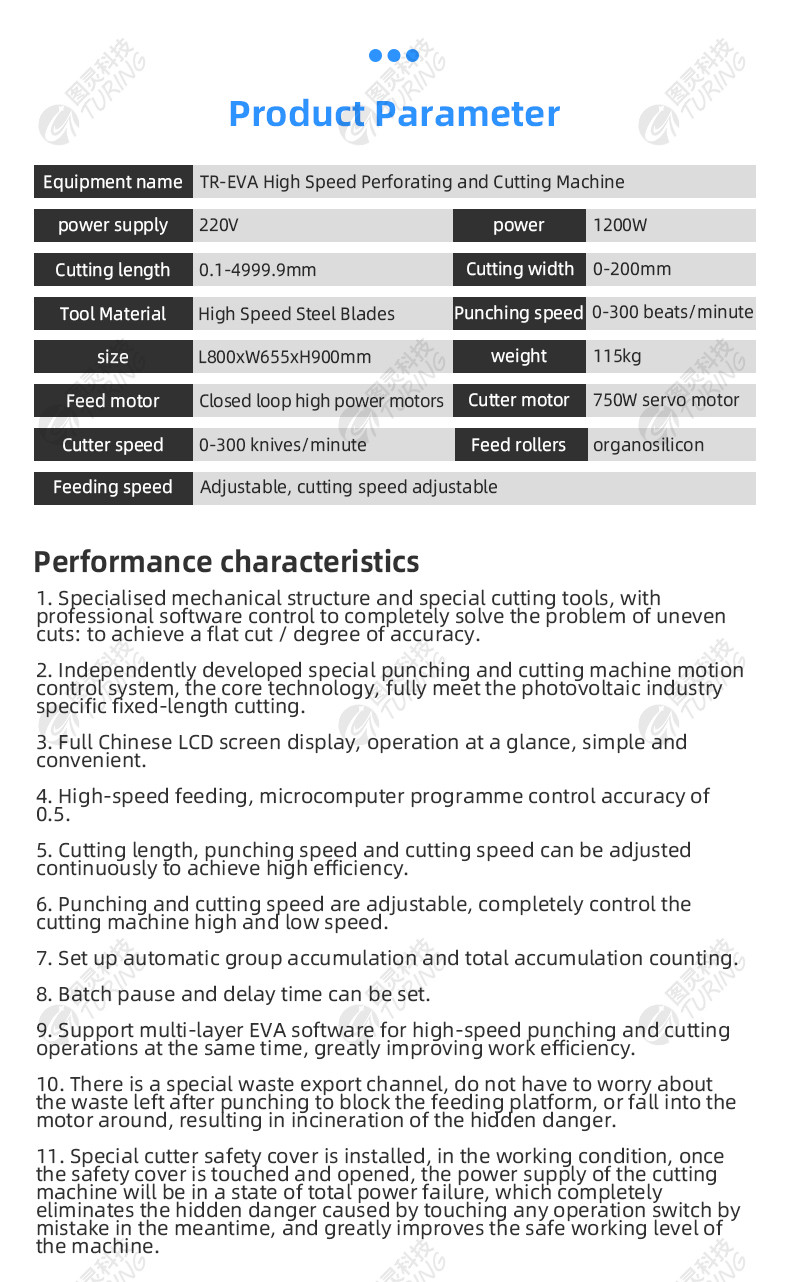

Power supply: 220V

Cutting length: 0.1mm-----4999.9mm

Cutting width: 0--200mm;

Weight: 115KG

Knife material: high-speed steel blade

Feeding speed: adjustable, cutting speed adjustable

Specification: length * width * height L800 * W655 * H900 mm

Power: 1200W

Feeding motor: closed-loop high-power motor

Cutter motor: 750W servo motor

Cutting speed: 0-300 knives/minute

Feeding roller: polyurethane

Punching speed: 0-300 times/minute

Performance characteristics

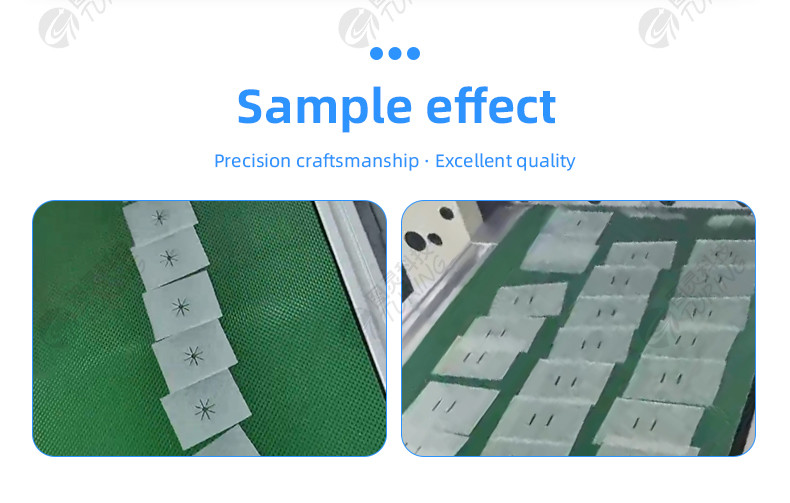

1.Specialised mechanical structure and special cutting tools, withprofessional software control to completely solve the problem of unevencuts:to achieve aflat cut /degree of accuracy.

2.independently developed special punching and cutting machine motioncontrol system, the core technology, fully meet the photovoltaic industryspecific fixed-length cutting.

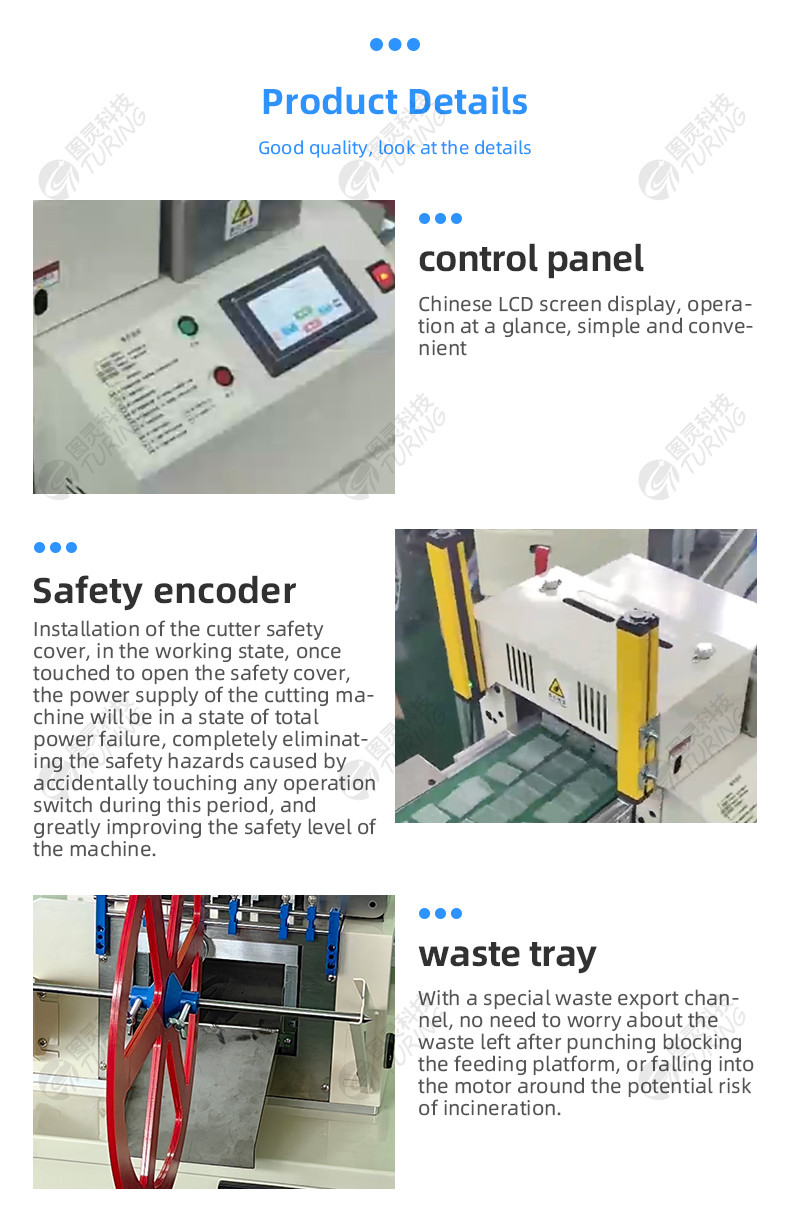

3. Full Chinese LCD screen display, operation at a glance, simple andconvenient.

4. High-speed feeding, microcomputer programme control accuracy of0.5.

2. ctmin sryton shiece nie seeec and cutting speed can be adjusted

e. nine mac ane high, enceed ae adjustable, completely control the

7.Set up automatic group accumulation and total accumulation counting.

8. Batch pause and delay time can be set.

9.Support multi-layer EVA software for high-speed punching and cuttingoperations at the same time, greatly impróving work efficiency.

10. There is a special waste export channel, do not have to worry aboutthe waste left after punching to block the feeding platform, or fall into themotor around, resulting in incineration of the hidden danger.

11.Special cutter safety cover is installed, in the working condition, oncethe safety cover is touched and opened, the power supply of the cuttingmachine will be in a state of total power failure, which completelyeliminates the hidden danger caused by touching any operation switch bymistake in the meantime, and greatlyimproves the safe working level ofthe machine.

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat shrink tube baking machine

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content