Home / All / Others / Foaming Machine /

TR-12 Full polyurethane Rail Foam Production Line/PU pillow foaming machine

TR-12 Full polyurethane Rail Foam Production Line/PU pillow foaming machine

Detail Information

TR-12 Full polyurethane Rail Foam Production Line/PU pillow foaming machine

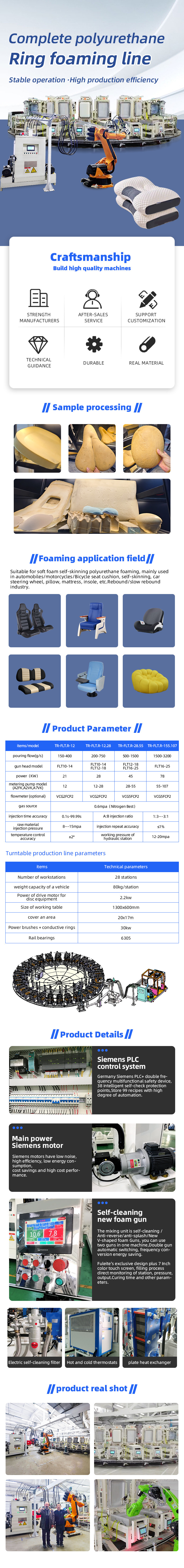

Complete polyurethane Ring foaming line/PU Pillow Foaming Production Line

Suitable for soft foam self-skinning polyurethane foaming, mainly usedin automobiles/motorcycles/Bicycle seat cushion, self-skinning, carsteering wheel, pillow, mattress, insole etc.Rebound/slow reboundindustry.

Product Features of PU High Pressure Machine:

1. Adopting three-layer storage tank, stainless steel shell, outer heating sandwich type, wrapped with a layer of insulation, adjustable temperature, safety and energy saving;

2. Adding material sample testing system, which can be exchanged freely without affecting normal production, saves time and material;

3. Low speed high precision pump measurement, accurate proportion, random error within ±0.5%;

4. Material flow rate and presure adjusted by motor converter with variable frequency regulation, high precision, simple and quick ration adjustment;

5.High-performance mixed device, accurately synchronous output of materials, even mixing. New watertight structure, cold water cycle interface reserved to ensure no obstruction during long downtime;

6. Adopting PLC and touch screen human-machine interface to control injection, automatic cleaning and air discharge, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors.

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat shrink tube baking machine

- Pay-off rack

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content