Home / All / Inserting Tube Machine and Heat Shrink Tube Baking Machine /

TR-HM01 Semi-Automatic Ribbon coding sleeve number tube baking machine

TR-HM01 Semi-Automatic Ribbon coding sleeve number tube baking machine

Detail Information

TR-HM01 Semi-Automatic Ribbon coding sleeve number tube baking machine

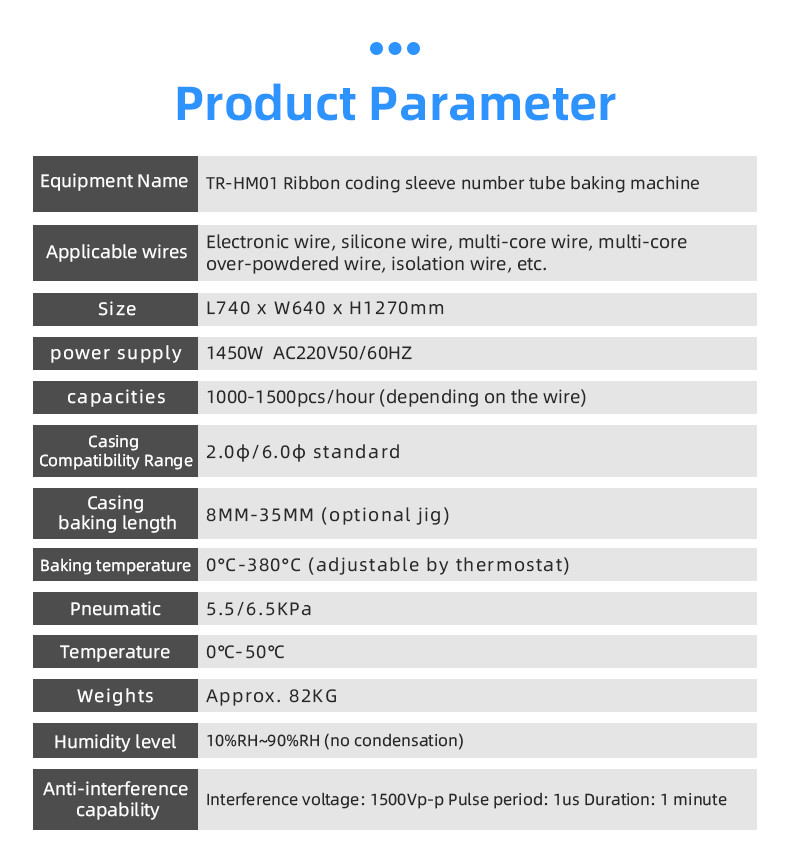

Applicable wires:Electronic wire, silicone wire, multi-core wire, multi-core

over-powdered wire, isolation wire, etc.

Size & weight:L740 x W640 x H1270mm,Approx. 82KG

power supply:1450W AC220V50/60HZ

capacities:1000-1500pcs/hour (depending on the wire)

Casing

Compatibility Range:2.0φ/6.0φ standard

Casing

baking length:8mm-35mm (optional jig)

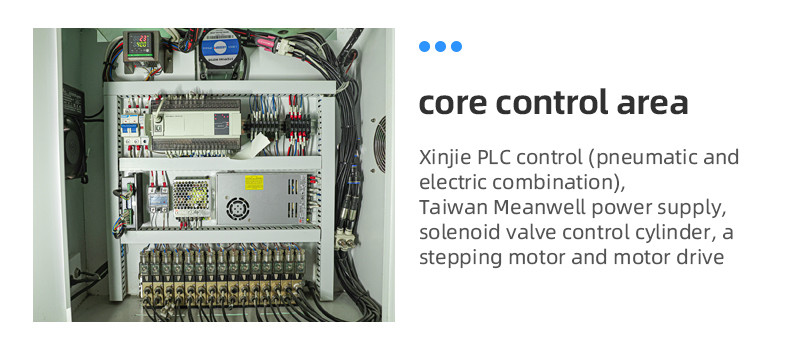

Baking temperature:0°C-380°C (adjustable by thermostat)

Pneumatic:5.5/6.5KPa

Temperature:0℃-50℃

Humidity level:10%RH~90%RH (no condensation)

Anti-interference

capability:Interference voltage: 1500Vp-p Pulse period: 1us Duration: 1 minute

Product Description

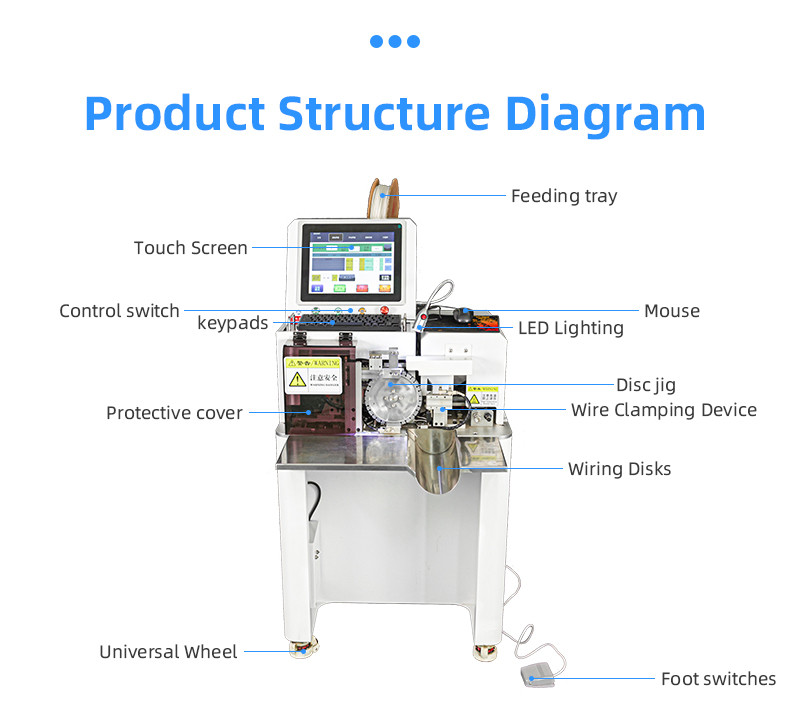

1. Industrial automation PLC, industrial control integrated machine is controlled by the host computer software, which is simple to operate, stable in work and high in efficiency.

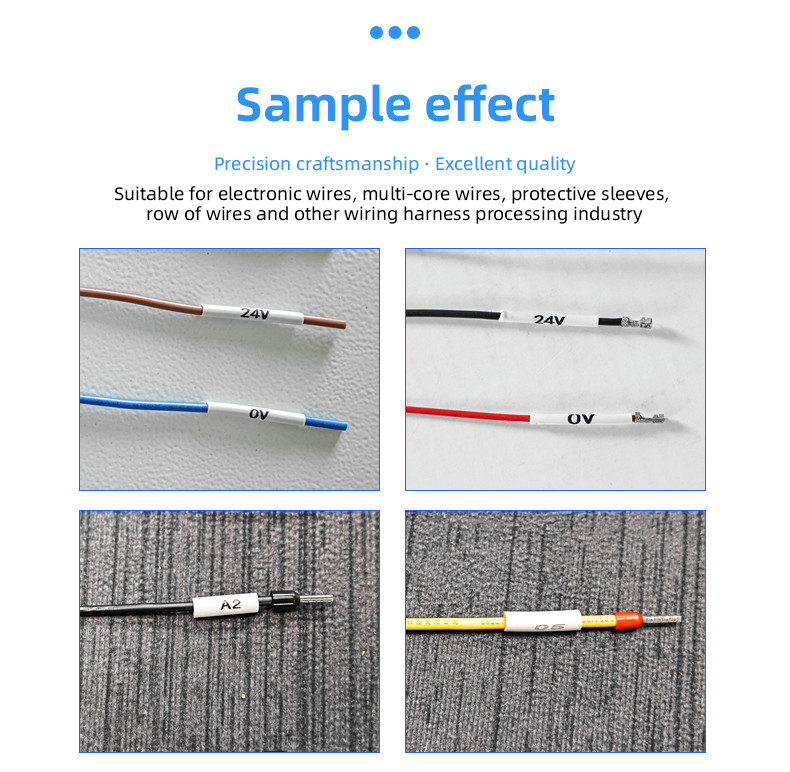

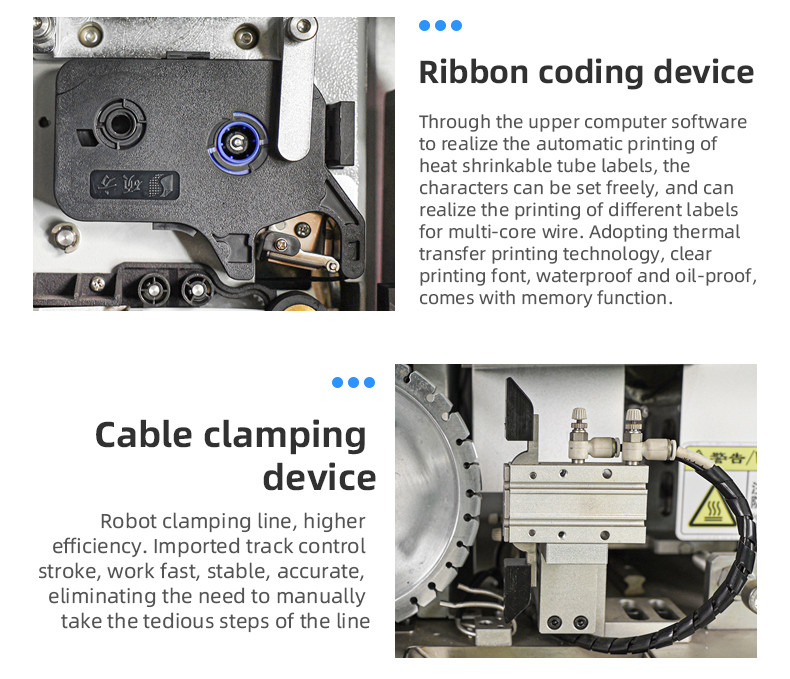

2. Automatically print heat shrink tube labels through the host computer software, and the characters can be set freely. At the same time, different label printing for multi-core wires can be realized, heat shrink tubes can be automatically loaded and cut, and the baking length can be freely set with the jig. Adjust the baking position through the positioning device.

3. The production capacity can reach 700-1500 terminals/hour (depending on the manual on-line speed).

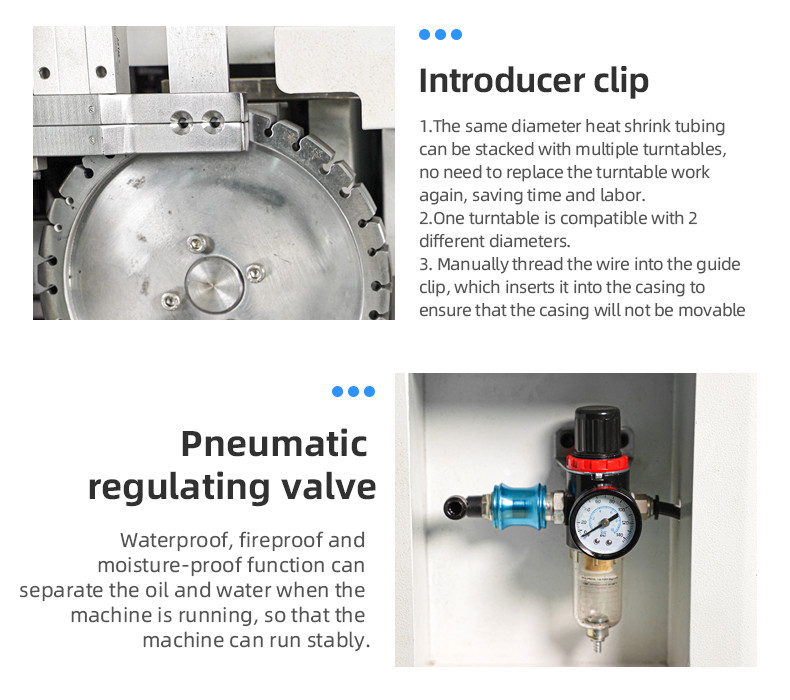

4. The equipment has great compatibility, and the processing of various specifications of line materials can be realized by replacing the jig.

Features

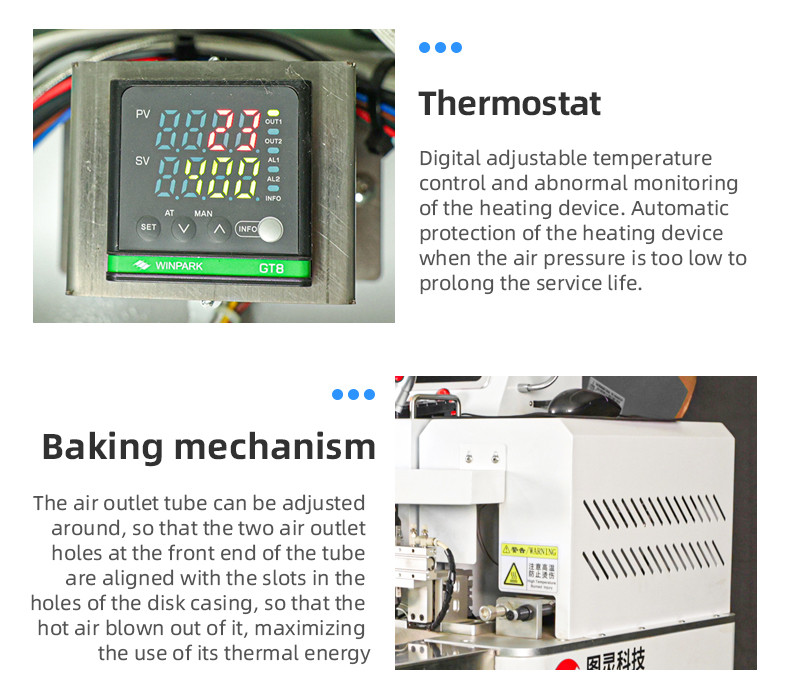

1. All series are equipped with a robot automatic thread taking device as standard. (Select and use based on standard wires, excluding automatic wire picking of special wires)

2. The printer we use is thermal transfer printing technology, which prints clear fonts, is waterproof and oil-proof, and has a printing accuracy of 300dpi and a built-in memory function.

3. The printing consumable is an integrated ribbon snap-on installation, which is simple to install and remove. It provides a variety of printing colors (black, white, red) to choose from to meet more process requirements.

4. Digitally adjusted temperature control and abnormal monitoring of heating devices. The heating device automatically protects the air pressure when it reaches the bottom, extending the service life.

5. Prevent operators from making mistakes in adjusting process parameters, and the system can be restored with one click.

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat shrink tube baking machine

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content