Home / All / Terminal Crimping Machine / Semi-auto Copper Strip Crimping Machine /

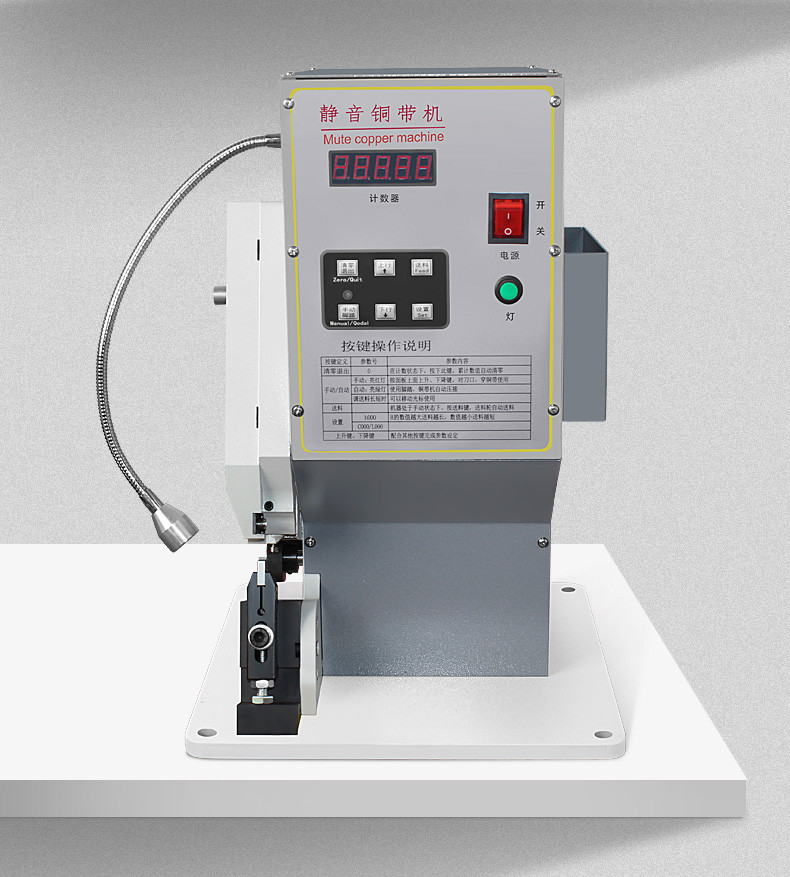

TR-JT23 Semi-Automatic Mute Copper Tape Crimping Machine

TR-JT23 Semi-Automatic Mute Copper Tape Crimping Machine

Detail Information

TR-JT23 Semi-Automatic Mute Copper Tape Crimping Machine

copper belt crimping, copper wire joint splicing machine cables terminal making machine

Features:

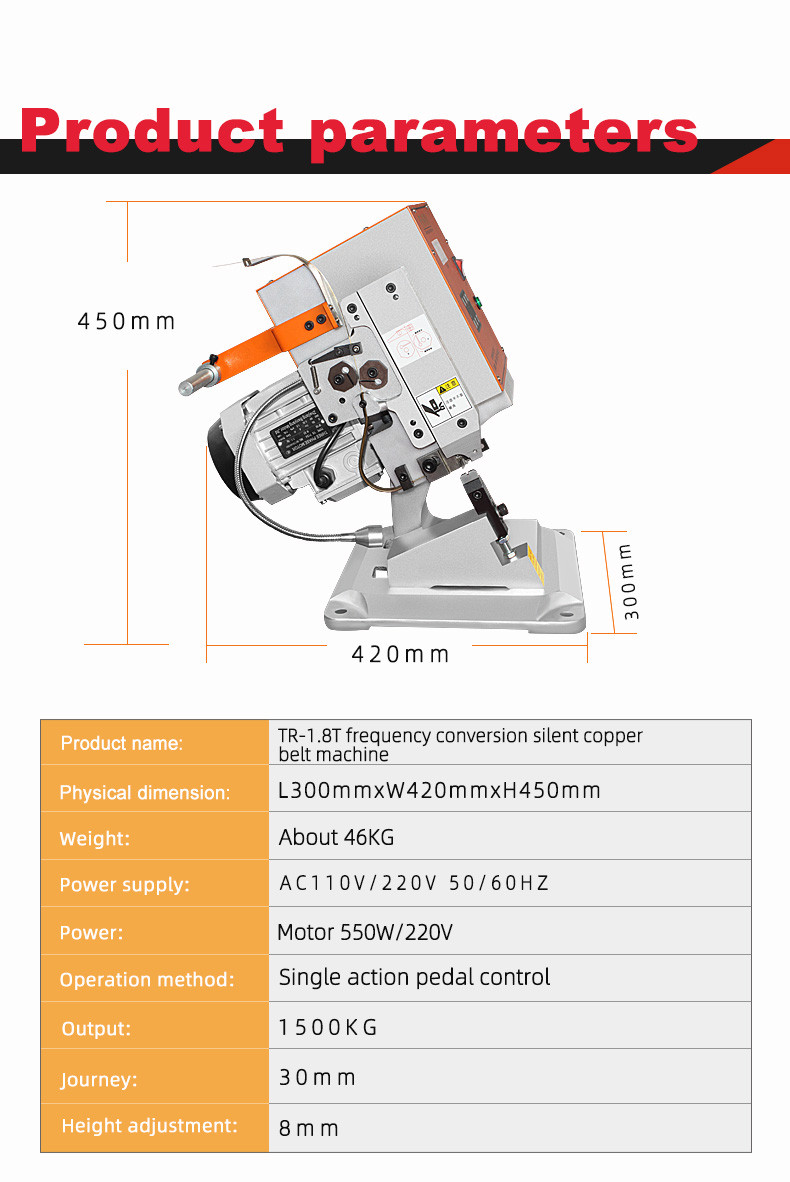

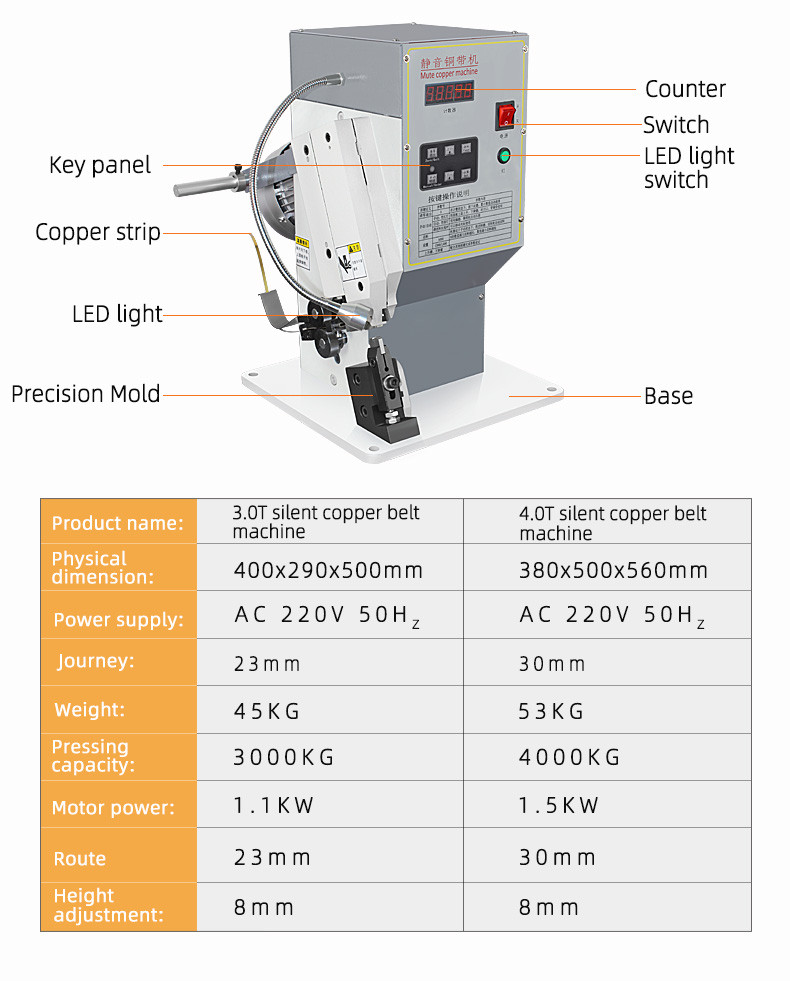

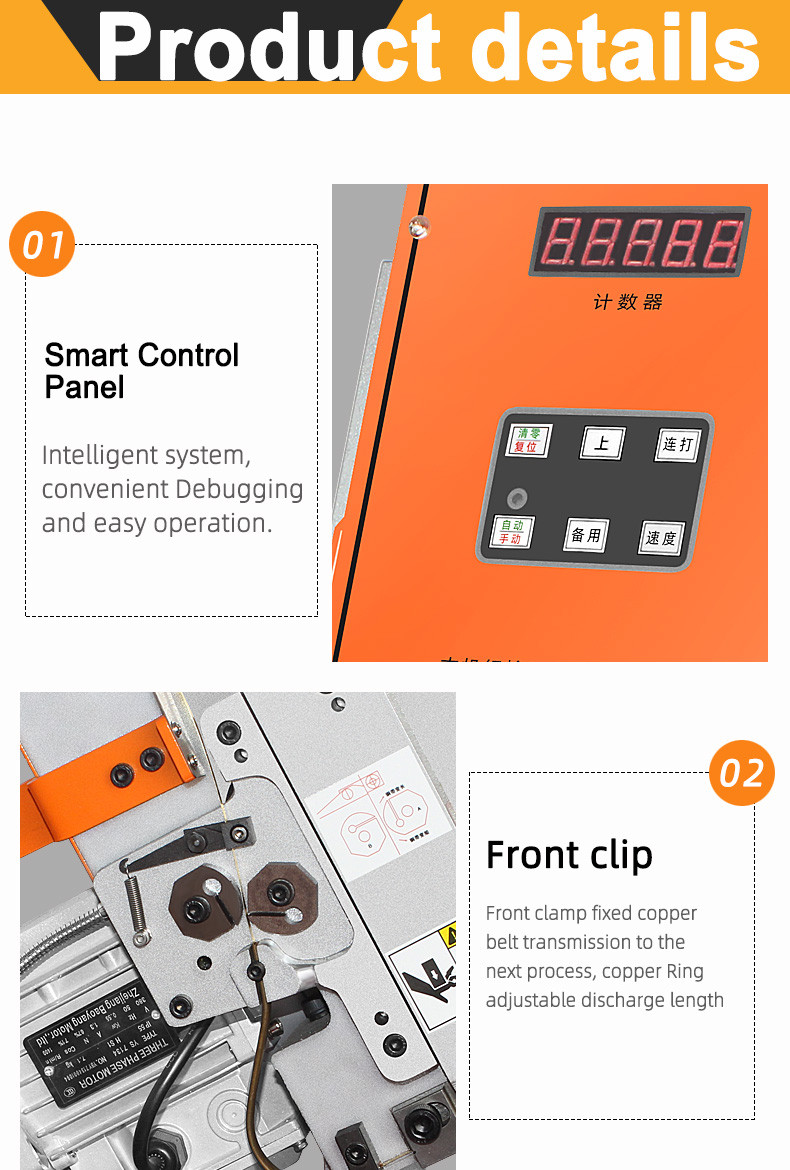

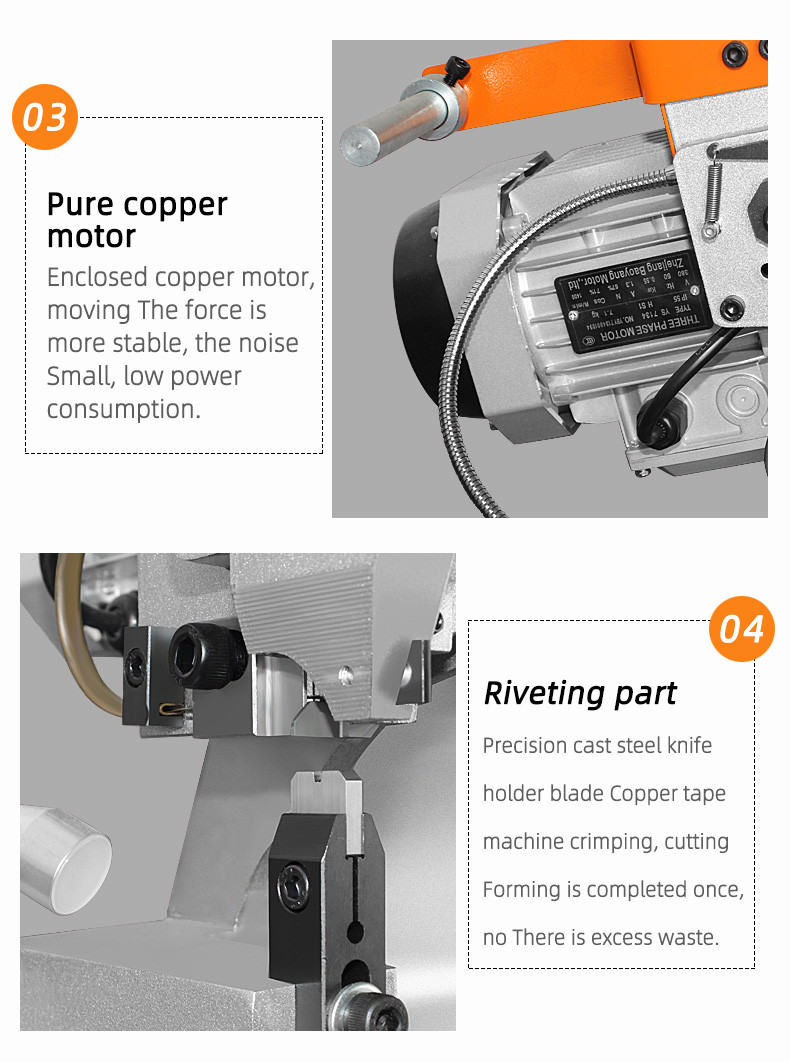

Adopting high-tech frequency conversion technology; electronic precise positioning; when the motor is crimped, the noise is smaller than the traditional copper belt machine, and it saves electricity; the mold adjustment is more convenient and quick; avoid the common failures of the traditional terminal machine clutch, electromagnet, etc.!

1. This machine is specially designed for wires that need to be processed by fusion, with fast speed and good quality;

2. The wire is connected by the crimping method, replacing the traditional soldering method, without the shortcomings of cold welding, air welding, and air pollution. It is the easiest and most effective way to pass various safety standard tests;

3. The use of special continuous copper tape terminals (patents are on file, please do not counterfeit) materials are cut, formed, pressed, and completed at one time, quickly and without waste, saving costs;

4. The copper strip terminal has been treated with special textures and has strong tensile strength after being folded, and the quality is stable;

5. It is suitable for earphone cables, data cables, electronic cable docking, resistance/lamp docking, automobile wiring harness, etc., humanized design, without training, can be operated at any time.

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat shrink tube baking machine

- Pay-off rack

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content